Breadcrumb

Case study on PET foamed products: Saving production costs by 20 %

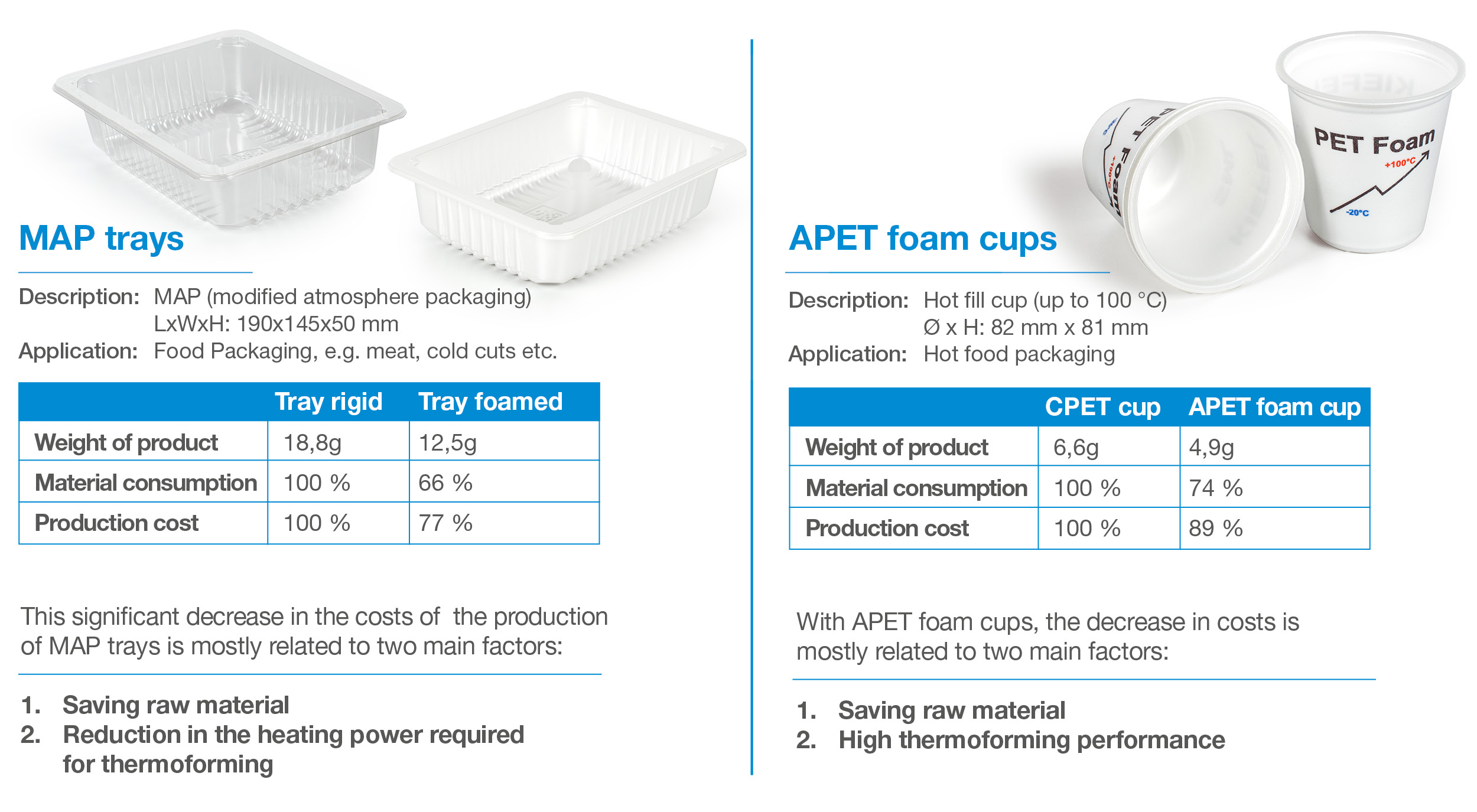

Common case studies from SML and the thermoforming specialists Kiefel B.V. on the manufacturing process of PET foamed products confirm 20 % lower production costs, compared with articles from conventional thermoforming sheet. And raw material consumption is even reduced by more than 30 %.

“The use of foamed sheet in the thermoforming process for applications like hot-fill cups or MAP trays does not only help to cut overall production costs. In the light of the ongoing discussions about consumers’ plastic footprint, easy-to-recycle foamed PET sheet can be a sustainable alternative to conventional thermoforming sheet”, Max Phillip Lutz, Product Manager Sheet Extrusion at SML, says.

APET foamed regrind from skeleton and edge trims can also be used up to 100 %. To prove these statements, SML and its cooperation partner has conducted the following case studies on APET foam cups and foamed MAP trays.

Fast changeover from foamed to rigid sheet

SML’s PET sheet lines for foamed APET sheet are also capable of producing conventional APET sheet for thermoforming applications. The changeover time between rigid and foamed is less than 20 min. PET foamed products are part of a new generation of plastics products which are ready to demonstrate their benefits in two major fields: in raw material consumption and recyclability.

Redlham, May 2021