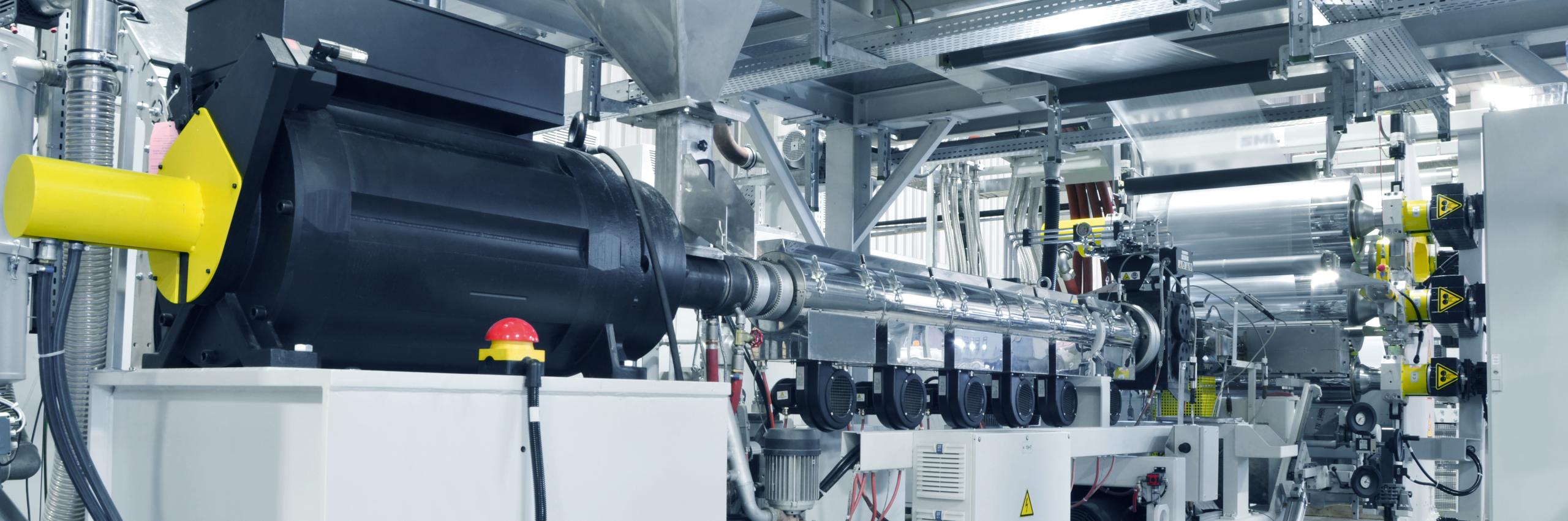

- Sheet lines

- PP / Barrier Thermoforming Sheet

PP / Barrier Thermoforming Sheet

The benchmark for perfect packaging.

Cups, lids, trays and blister packs are produced from sheet in large volume in a subsequent thermoforming process. With SML sheet lines, both thermoforming companies and sheet manufacturers have the optimum tool in hand to achieve high-quality results in the final packaging product. We have built up a vast wealth of experience during many years in this area, and can offer inline or offline solutions to our customers.

Irresistibly high output.

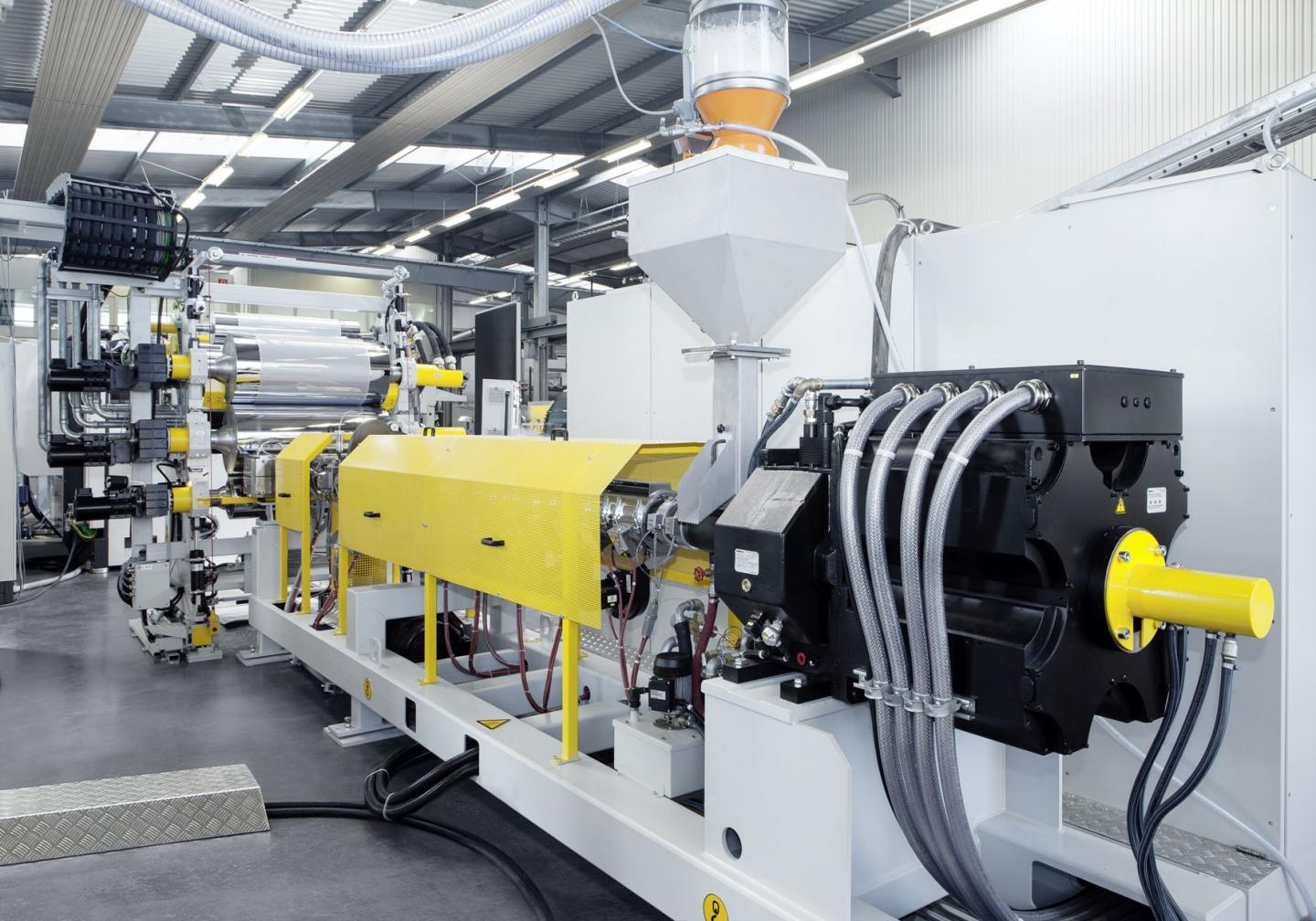

Our high-speed extruders (HSE), with screw diameters of 75 mm or 90 mm, have been specially developed for these sheet lines and will take your production to new levels.

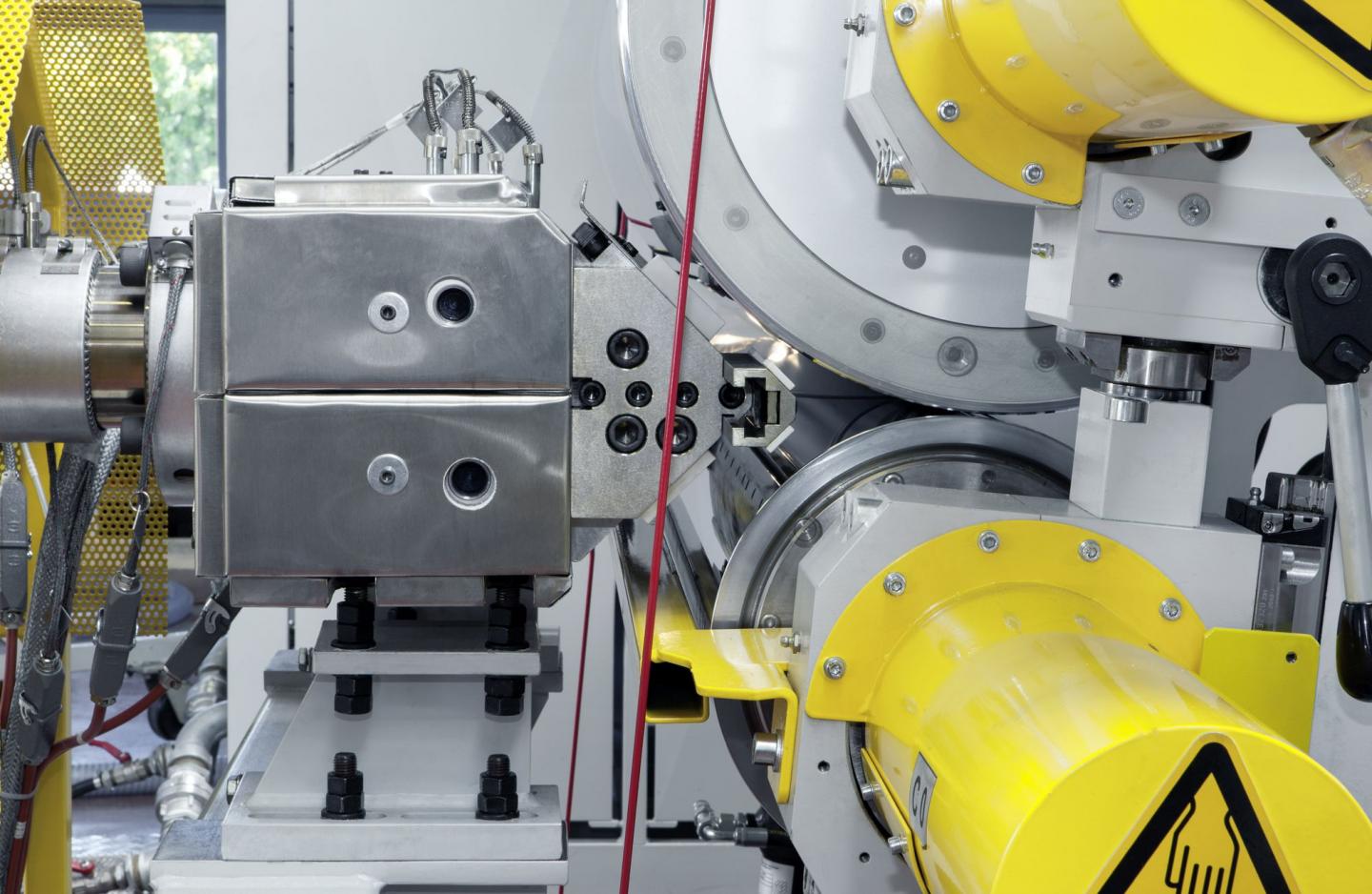

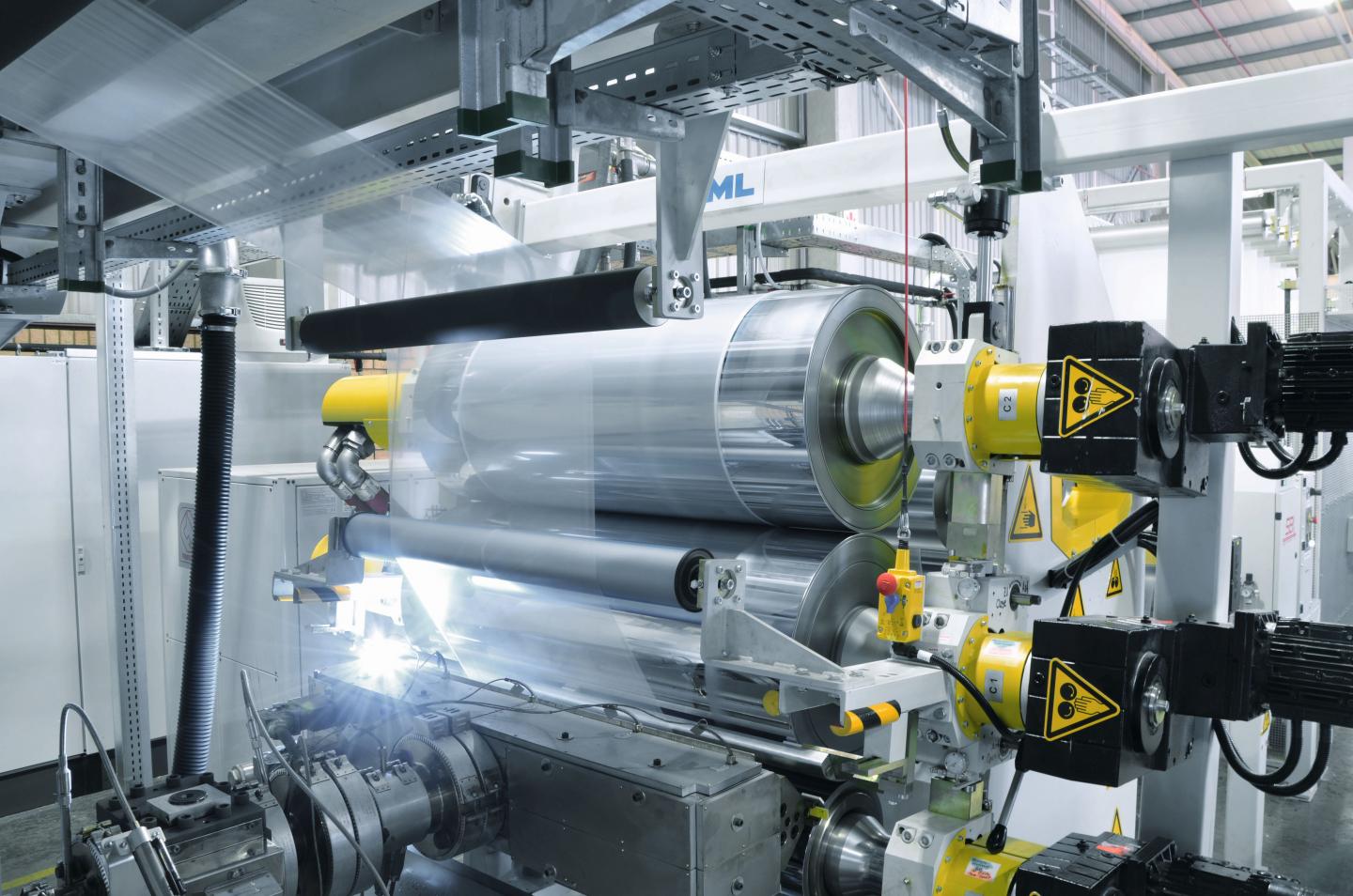

SML roll stacks are in a class of their own. With the Smart Parallel Gap (SPG) roll we have developed a particular highlight, guaranteeing perfect thickness tolerances with easy adjustments every time. Our high-performance roll stacks allow you to produce up to 3,000 kg/h per meter of sheet width.

Line Types

Top performance for ideal results.

High-performance class sheet lines

Our high-performance extrusion sheet lines never compromise on delivering the best sheet quality. They are designed for minimum energy consumption at maximum production capacity. These lines give our customers decisive advantages even in the toughest competitive environments, standing out from the pack.

| Polymer | production performance (at 1 m sheet width) |

|---|---|

| PP | up to 3,000 kg/h |

| TSL-1 Jumbo | TSL-2 Jumbo | |

|---|---|---|

| Extruder | 1 x HSE75 | 3x HSE75 |

| Extrusion performance | 1,350 kg/h | 3,000 kg/h |

| Sheet thickness range | 200 - 2,500 µm | 200 - 2,500 µm |

| Max. mechanical line speed | 70 m/min | 70 m/min |

| Winding diameter on 6-inch shafts | up to 2,000 mm | up to 2,000 mm |

Compact design to benefit your bottom line.

Economy class sheet lines

Our economy class sheet line, including a high-speed extruder (HSE), is especially well suited to all applications with limited numbers of layers and moderate output requirements. The system’s special attribute is its compact design and easy handling in daily operation.

| TSL-Eco Jumbo | |

|---|---|

| Extruder | 1 x HSE75 |

| Extrusion performance | 1,000 kg/h |

| Sheet thickness range | 200 - 2,500 µm |

| Winding diameter on 6-inch shafts | up to 2,000 mm |

The roll stack with vertical roll arrangement makes it possible to set up the extruder right on the shop floor, allowing the sheet extrusion line to be operated without a problem – even in workspaces with low ceilings.

Specific attributes

- Modular design

- Main extruder, pump, die and electrical cabinets on one frame

- Vertical roll stack, 1,200 mm roll width

- One control panel on the roll stack

Our benchmark for top quality.

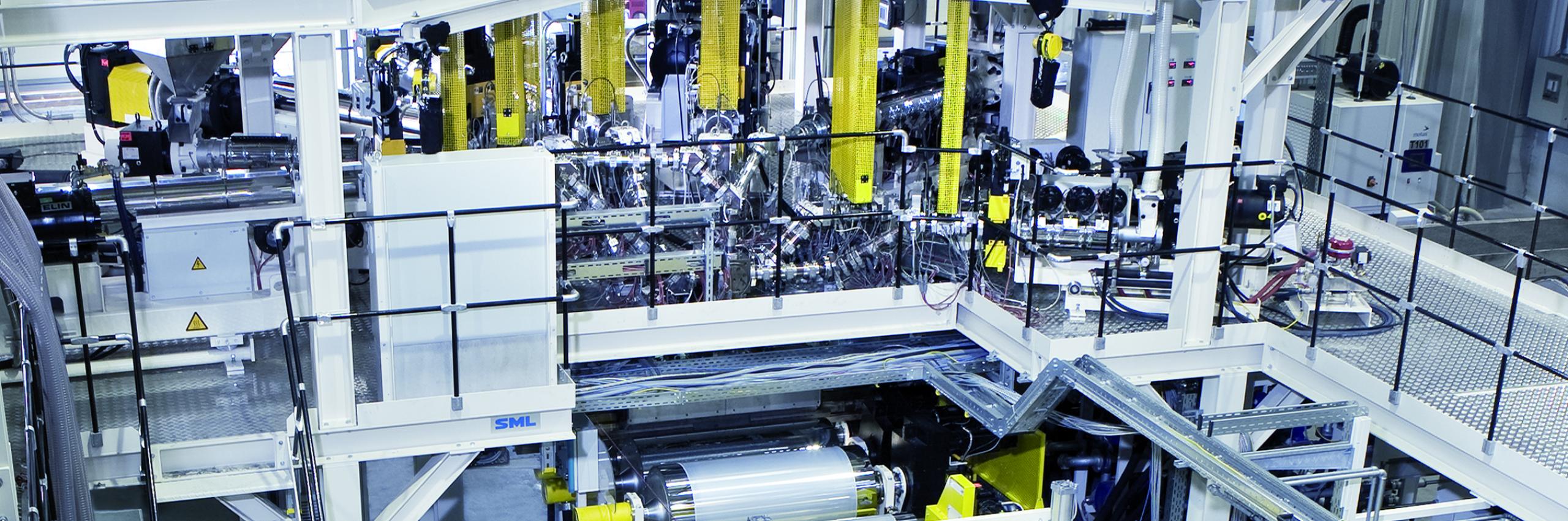

Barrier sheet lines

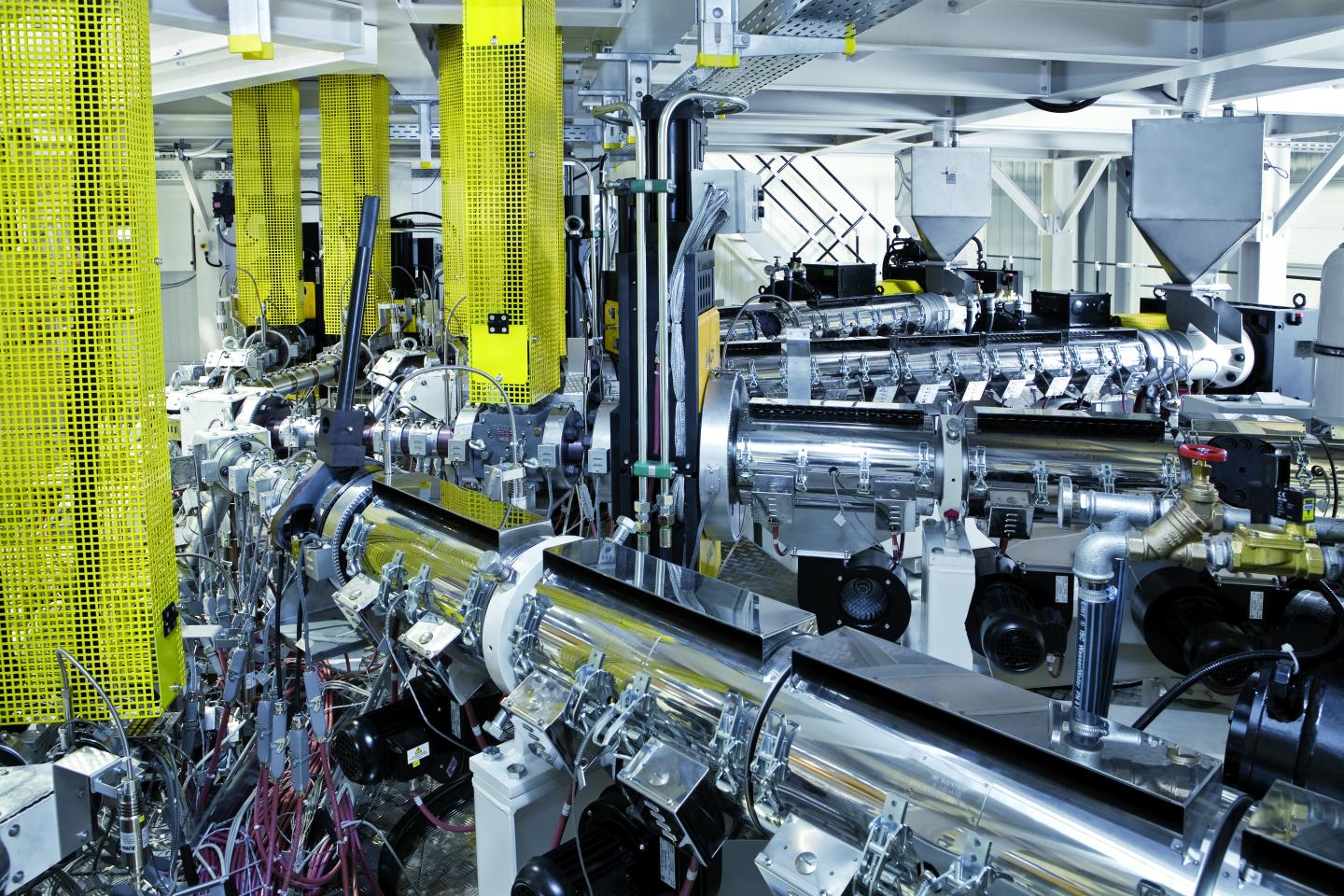

When the highest level of quality is demanded, we at SML are in our element. Barrier sheets are subject to particular quality requirements. These can only be met by systems combining components that are a perfect fit for one another, producing the results that are in greater demand than ever before in the food and packaging industry: lower weight, less material use and strong protection from outside factors.

Our engineers have a vast and varied wealth of knowledge at their disposal, enabling them to perfectly design multilayer barrier sheet lines dedicated to your specific demands and markets. And this knowledge will pay off for you too.

Unique performance outcomes for quality products

- Up to 9 extruders creating sheet with up to 11 layers

- A roll stack in a class of its own: up to 3,2 t/h

- HO-LT extruder (High Output - Low Temperature) for maximum output at a low production temperature for heat sensitive materials such as EVOH

- Efficient concepts for the direct re-use of edge trims and skeletons in intermediate layers

Efficiency in its purest form.

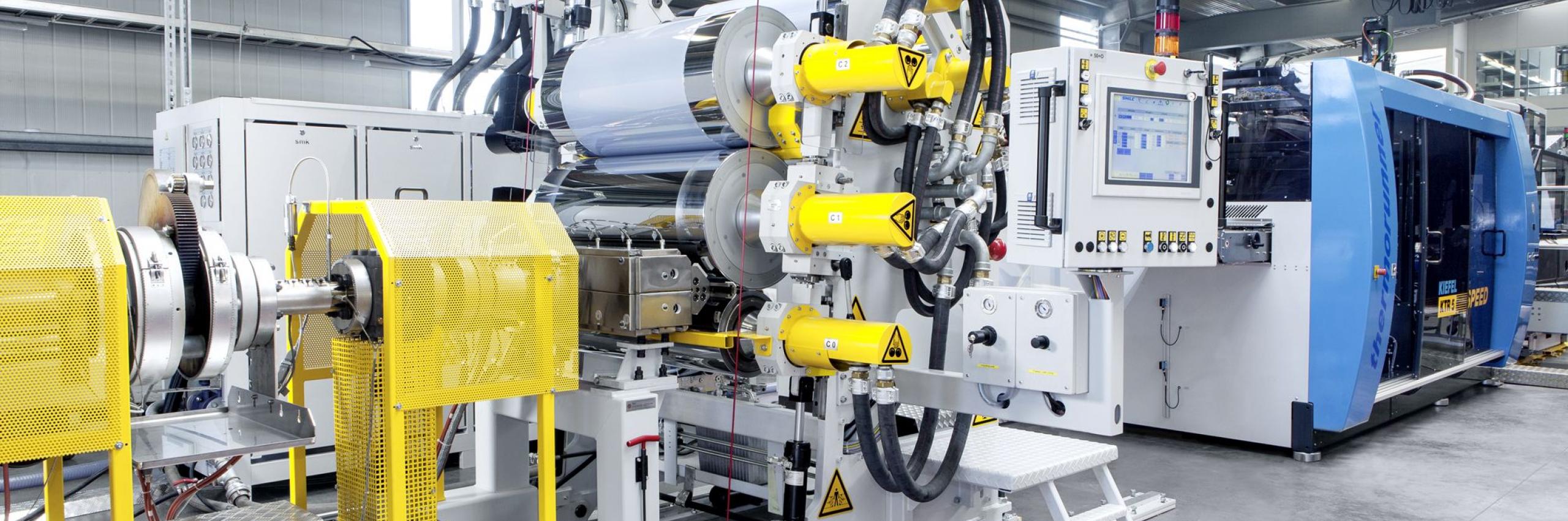

Inline extrusion sheet lines

If you wish to produce large volumes of cups or trays without the need for product changes, you will not want to miss out on our inline sheet extrusion lines. A direct connection between the extrusion line and a thermoformer is the most efficient way of producing these products in a continuous process. We work together closely with all the well-known thermoformer manufacturers. As a result, you will always be sure to receive the best possible all-round solution – especially for the sake of your productivity.

| I-TF2 | I-TF3 | |

|---|---|---|

| Extruder | HSE75 | HSE75, HSE90 |

| Extrusion performance | 600 kg/h | 900 kg/h |

| Co-extruder (option) HighOutput - LowTemperature | HO-LT | HO-LT |

| Roll stack | SPG300/400/400 mm | SPG300/490/490 mm |

Sheet lines that are efficient to the core – the details do not lie

- Highest transparency and rigidity for cups and trays

- Most energy-efficient process

- Efficient use of polymers thanks to direct skeleton recycling

- Compact line design requiring less space

- No winding, no roll handling, no need for warehouse space