Breadcrumb

Which material is best for disposable coffee cups?

Comparing PS, PP, PET and 'paper'

According to the consultants, Research Nester, the market share for disposable cups will more than double from 13.45 billion USD in 2024 to 31.68 billion USD by 2037. Good thermal properties, health safety and easy recyclability are essential properties for disposable coffee cups.

“For several years now SML has been developing processes to manufacture heat-resistant materials for applications such as coffee cups on its own sheet lines. Meanwhile, thermoforming companies dispose of several different materials to manufacture cups in line with changes in market demands and in compliance with increasingly stringent environmental regulations,” Rupert Becker, the Product Manager for sheet lines at SML, explains. But what might be the optimum material for the coffee cups of tomorrow?

Cups from rigid PS

Conventionally, disposable coffee cups were mainly made of polystyrene (PS), which is relatively easy to thermoform. Polystyrene has, however, fallen from favour among several FMCG (Fast-Moving Consumer Goods) manufacturers due to potential health safety issues. Coffee cups made of polystyrene can release odours and may affect the taste. The material can be recycled, but post recycling applications are limited.

PP-foam cups

To create a future-oriented and environmentally acceptable alternative to rigid PS products, SML has developed a new method to manufacture PP foamed materials. PP-foam coffee cups are made from 3-layer PP sheets. The central layer is physically foamed while the outer layers are rigid. The sheet is extruded using flat die coextrusion technology in combination with a gas injection unit. To create the specific cell structure of the foamed inner layer, a gas such as nitrogen is used. Coffee cups from foamed PP have excellent insulation properties and are heat-resistant up to 100 °C. Compared with cups from 100 % rigid PP, PP-foam cups have a significantly lower density and lower weight. This means that less material is required to produce these. In addition, PP-foam sheet is very easy to thermoform. When it comes to recycling, a major advantage of PP-foam materials in comparison to other foamed plastics is that they can be sorted by the regular process in waste sorting plants.

PET-foam cups

The same thing that worked with PP also works with PET. As a next step, SML developed cups of mono-material PET-foam sheet. PET-foam sheet is not transparent, manufacturing processes and material properties are very similar to those of PP-foam sheet. PET foamed sheet can consist of up to 60 % recycled PET, while still being in compliance with food safety standards. It cannot be sorted by gravity waste sorting plants due to its lighter weight compared to rigid PET.

C-PET light cups

C-PET light sheet is characterised by its suitability for transparent applications, high stiffness, and efficient production with a high output. The material is an economic and easy-to-recycle alternative to rigid PS and PP in thermoformed hot fill applications – such as coffee cups. C-PET light withstands temperatures of up to 100 ° C. In thermoforming, shorter cycle times represent an economic advantage compared with conventional C-PET. Due to the similar density of virgin PET and its transparency, coffee cups from rigid C-PET light can be easily sorted and recycled in existing facilities.

And what about “paper” cups?

Practically, all of the coffee cups made from “paper” are of paper coated with polymers, either PE or bio-based PLA. The function of the polymer coating is mainly to provide moisture resistance. So far, coffee cups from paper coated with plastics have become well established in the market. Their biggest disadvantage is the higher CO2 footprint of paper production and their limited recyclability since the polymer and the paper components of the cups have to be separated in a relatively complex process before recycling. Today, polymer-coated “paper” coffee cups are generally categorised as single use plastics in accordance with EU directive 2019/904 regardless of whether the coating is made of PE or bio-based PLA.

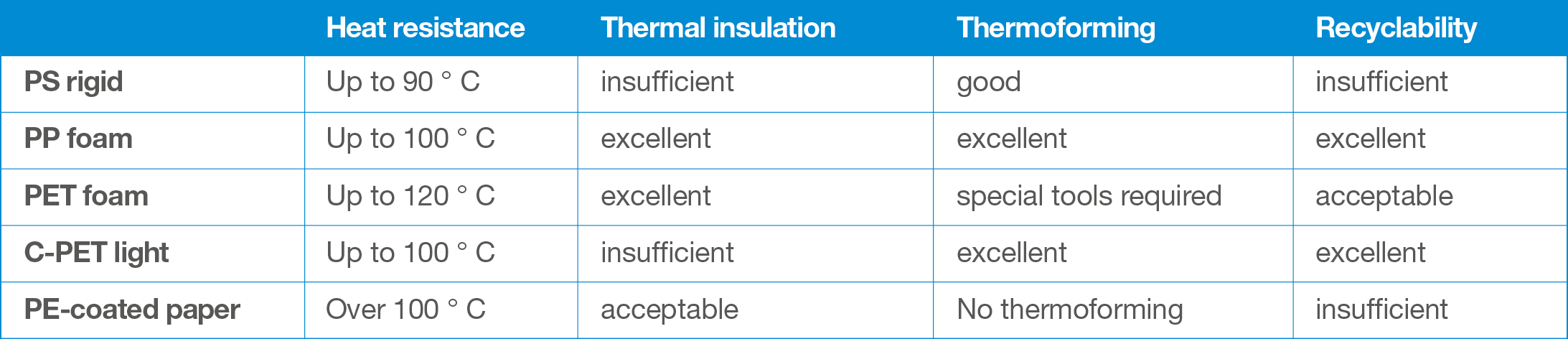

So, what is the best material for disposable coffee cups?

“Our different extrusion lines are able to produce practically any material for coffee cups - from rigid and foamed mono-materials to polymer-coated paper. The question of ‘Which material is best’ naturally depends to a large extent on the specific requirements of the material manufacturers, the thermoforming companies and the end-customers. However, if we try to weigh up the advantages and disadvantages of the individual materials, easy-to-recycle mono-material PP-foam has a lot in its favour”, Rupert Becker, the Product Manager at SML, confirms.

Redlham, 19.05.2025