Breadcrumb

FlexPack® coating line available for ongoing trial runs and product sampling

Last year, expectations were high prior to the launch of SML’s industrial scale FlexPack® pilot plant and in the meantime these expectations have not only been fulfilled, but surpassed! What’s more, the flexibility of the FlexPack® concept has been frequently confirmed by positive client feedback.

In view of this success, SML extended the availability to use the FlexPack® pilot line for ongoing, comprehensive test runs and product sampling.

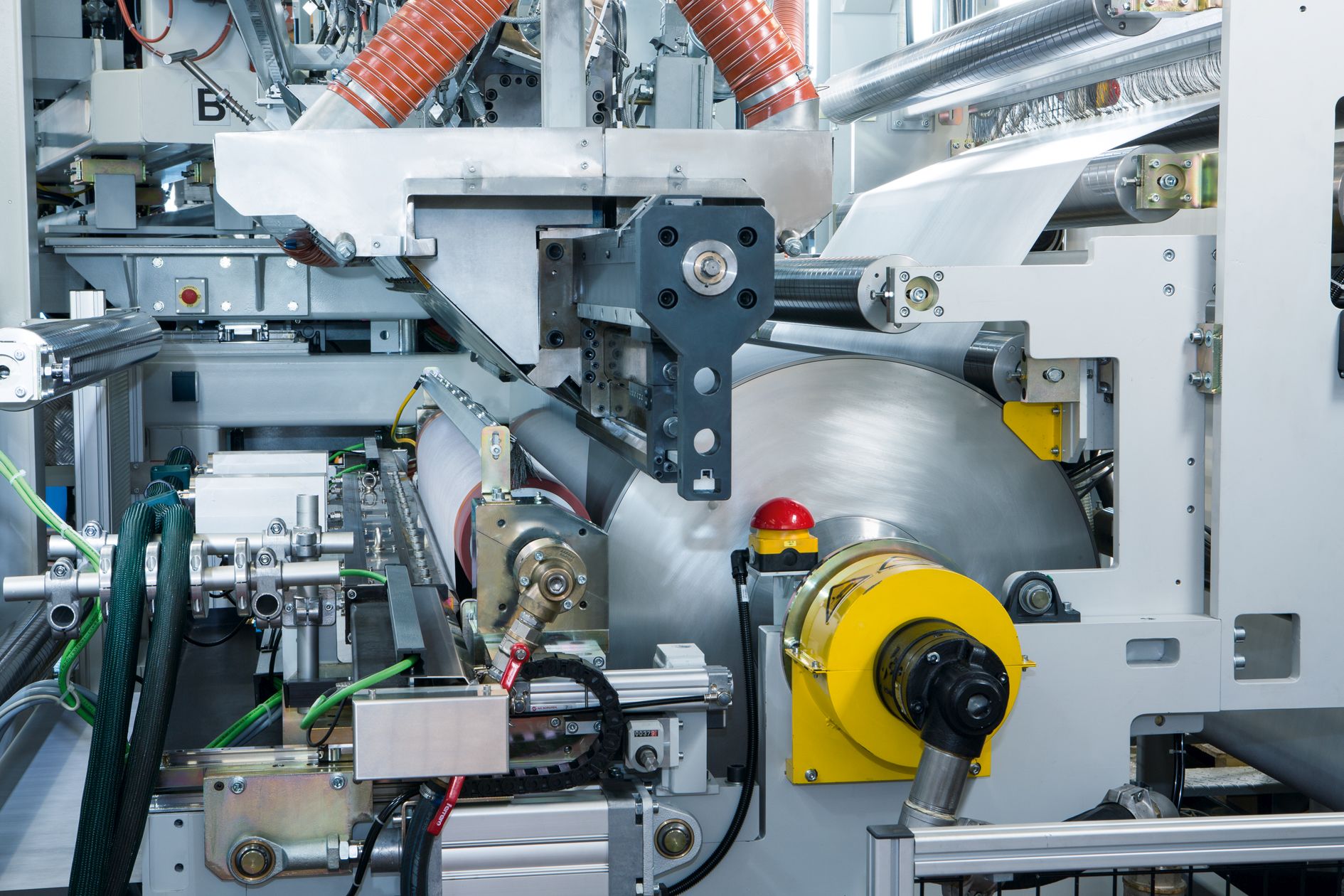

The FlexPack pilot line can handle substrate widths of between 800 and 1,650mm at production speeds of up to 450 m/min. User-friendly operation is ensured and key components in the line include fully automatic, shaftless turret unwinders, a primer station with a closed chamber doctor blade system, ozone treatment for the melt curtain and a shaftless winder at the end of the production process.

Compact design allows excellent accessibility, simple operation and a guarantee of the utmost flexibility for product changeovers, which reduces waste and maintains productivity at the highest possible level.

On the bottom line, these advances add up to a wealth of product possibilities such as flexible packaging based on paper, film and aluminium foil substrates, as well as technical or medical applications.

FlexPack® coating line + DoubleCoat = new product diversity

In addition, the “DoubleCoat” process, for which a patent is pending, can be integrated into the FlexPack® coating line in order to create fresh opportunities in the breathable product field. DoubleCoat combines extrusion coating with hot melt lamination and thus enables coating thickness minimisation, as well as product breathability enhancement.

The DoubleCoat and FlexPack® combination is not only suited to the manufacture of soft touch hygiene products such as for femcare articles, but also medical products that include surgical drapes, which although highly breathable serve as an effective barrier against viruses and bacteria.

Lenzing, 07.03.2017