对可持续发展的整体性理解——涵盖生态、社会与商业维度—— 已深深植根于 SML 的企业文化。可持续性理念已融入到公司的所有流程中,并成为我们开展日常活动的依据。我们全面贯

彻《欧洲可持续发展报告标准》 (ESRS) ,以此彰显对透明度与责任感的坚定承诺。”

在可持续发展目标中,我们聚焦以下核心领域:

秉持这一明确目标,我们致力于以前瞻眼光谋划发展——兼顾经济效益、生态相容与社会公平。

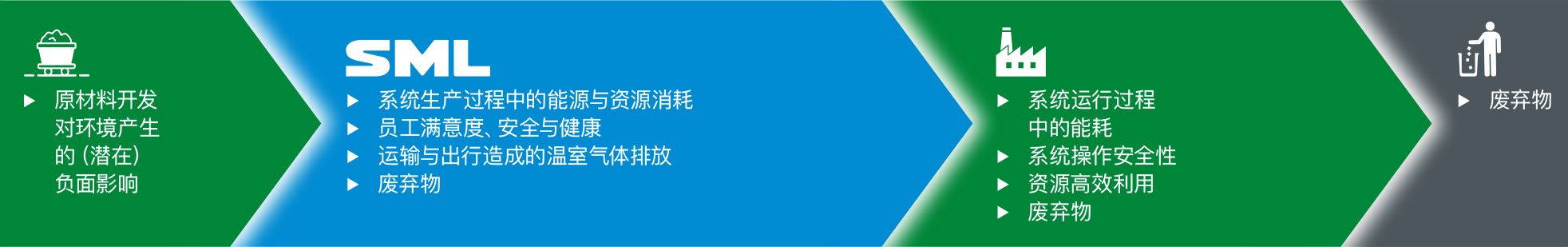

价值链中的责任担当

SML 将自己视为为塑料价值链中的积极参与者。我们不仅在自身组织内肩负责任,也在上下游流程中承担相应的义务。我们的《供应商行为准则》确保价值链上游环节同样遵循我们的社会与生态标准。

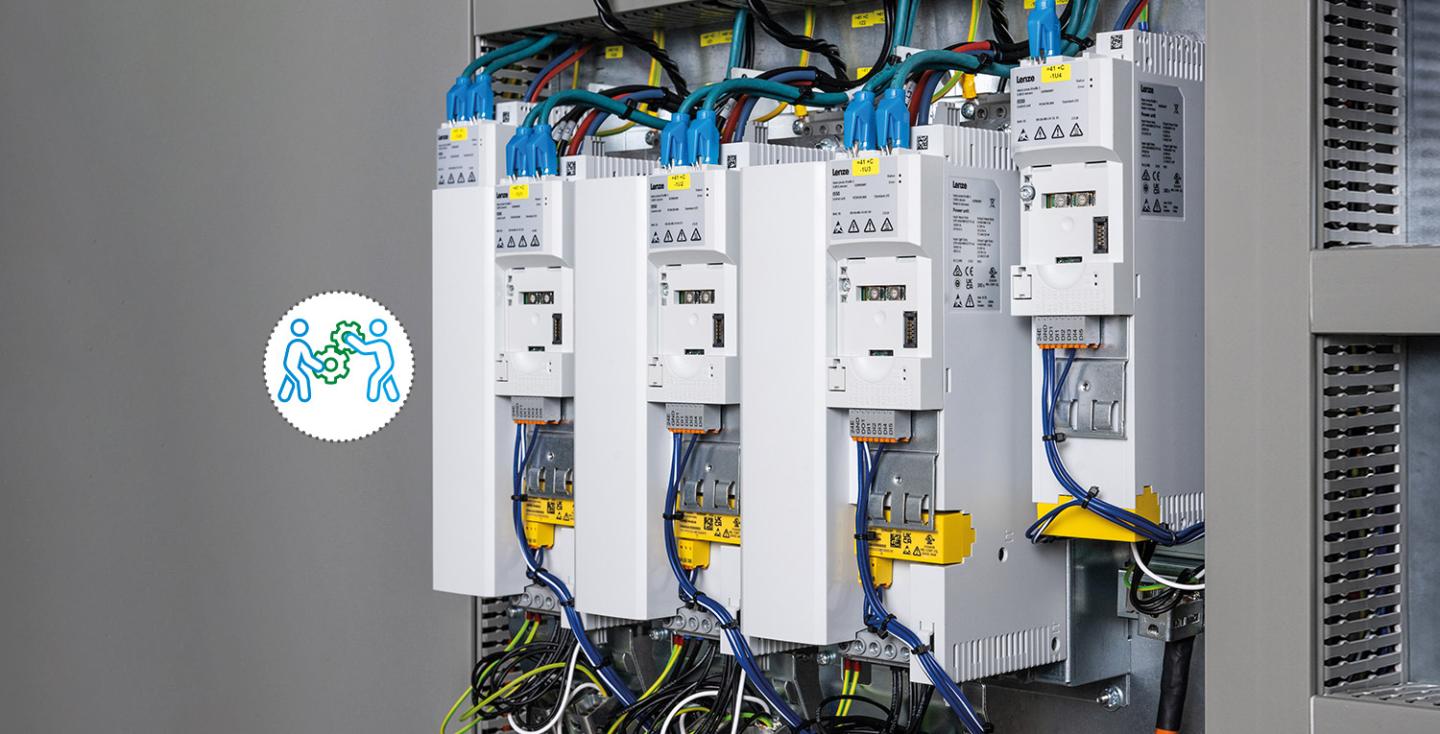

给人确定性和安全感

SML 致力于营造安全、稳定且相互尊重的工作环境。无论是在自身运营中,还是在开发人性化设备时,职业安全与健康始终是我们的重中之重。

我们的可持续发展目标包括加强内部培训和再教育、用国际化思维构建更具多元化的员工队伍。我们通过这些举措促进企业的长期发展和践行社会责任。