- Technology Centre

Technology Centre

Creating solutions together.

Our engineers and technicians relentlessly strive to craft the best solution for our customers. No matter the task or challenge you have in store for us, we will work together with you at the Redlham pilot plant to develop ideal solutions that go above and beyond the latest industry standards.

SML supports you to realise your ideas and test them sufficiently.

The production of customer samples, the common development of new products and joint test series plays a key role in SML’s partnership with its customers. Joint R&D activities facilitate the mutual understanding, and through it, the anticipative fulfilment of customer wishes. Not least, the findings generated together are having a direct impact on the further development of new machinery and technology at SML.

Line Types

Available demonstration line types:

Teaming up for innovations.

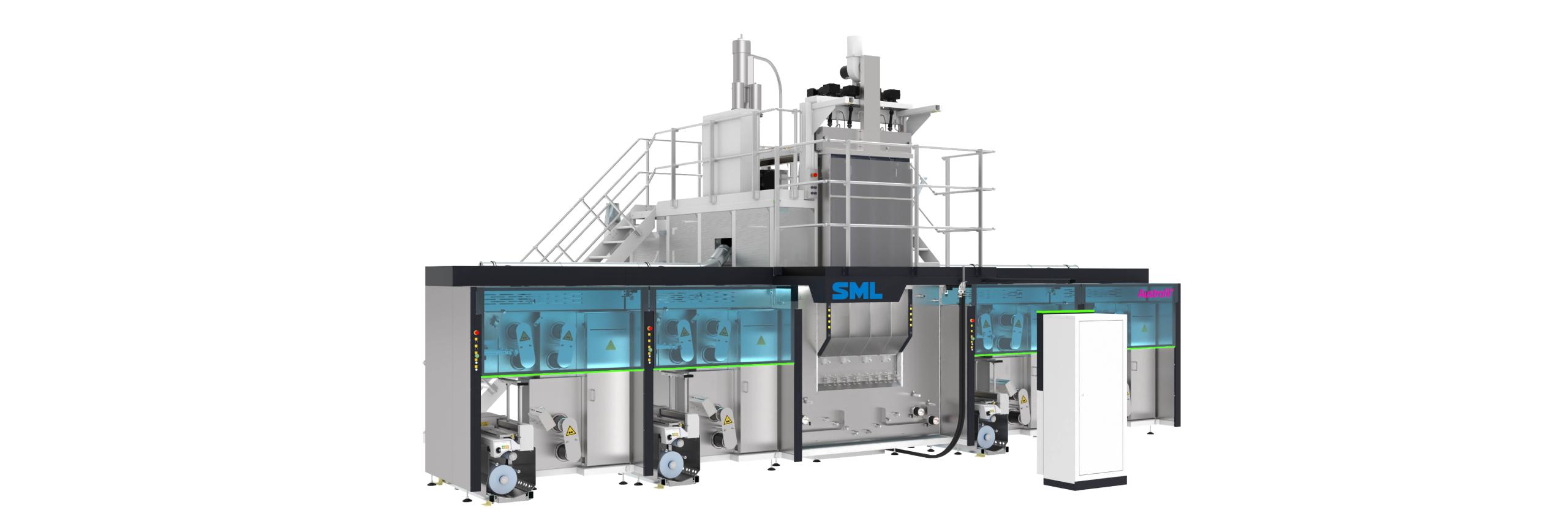

Advanced FlexPack extrusion coating and laminating line

A completely new production scale FlexPack extrusion coating and lamminating line is ready for performance tests, sample production and joint R&D projects.

The state-of the-art FlexPlack line features a number of technical innovations:

The plant is equipped with three extruders, that are configured to process a huge variety of different polymers - ranging from polyolefins to TPU, TPE, PET PLA and EVOH. The co-extrusion feeblock provides up to five layers, which enables the production of barrier-coated film for flexible packaging now. An additional single unwind is integrated for the production of reinforced laminates.

| Substrates | Paper, BOPP/BOPET film, Aluminium foil, Metallised film, Barrier film Laminates, Nonwovens, Scrim |

|---|---|

| Extrusion materials | LDPE, PP, EAA, EMA, EVA, IONOMERS,... |

| Max. line speed | 450 m/min. |

| Roller width | 1,800 mm |

| Substrate width | 700 - 1,650 mm |

| Coating weight | 8 - 50 g/sqm (depending on the product) |

Advantages of FlexPack :

- Reduced floor space requirements

- Good accessibility

- High quality components

- Easy operation

Small, compact, strong.

MiniCast stretch wrap film line

SML’s MiniCast demonstration line is primarily installed as a service to its customers for trial runs in production scale. State-of-the art technology is provided to find solutions to future challenges relating circular economy and sustainability in stretch film production.

Flexibility in production is given through the applied stretch film winder W4000, which significantly contributes to the lines over-all performance.

| Max. line speed | up to 650 m/min |

|---|---|

| Max. final width | 3 x 500 mm |

| Number of extruder | 3 |

The MiniCast demonstration line enables versatile research on

- testing and improving of new formulations

- processing of increased post-industrial / post-consumer recycled material content

- silage film

Fast & Flexible

EcoCompact Stretch Wrap Film Line

The EcoCompact stretch film line, which was completely revised in 2024, is now also available as a demonstration line for extensive trials to customers. With a width of 2 m the EcoCompact is perfectly suited for the fast and efficient manufacturing of 2” hand rolls, modified edges and coreless winding.

The W4000-4S2T winder with 2 turrets contributes considerably to the high flexibility of the EcoCompact in stretch film production.

| Max. line speed | 750 m/min |

|---|---|

| Max. final width | 4 x 500 mm |

| Number of extruders | 4 |

This demonstration line enables versatile possibilities on

- ultimate performance tests

- testing different polymers

- production of samples

High performance and flexibility

Austrofil HT spinning line

This Austrofil spinning line has been specially developed for the production of technical and textile yarns with high tensile strength. It has become a top seller with more than 200 machines sold worldwide. Its high speeds, broad titre range and excellent production stability have made a convincing impression.

This demonstration line enables versatile possibilities on

- ultimate performance tests

- testing different polymers

- production of samples

| Austrofil HT 4x2/4/75, 8/16 ends | |

|---|---|

| Polymer | Polypropylene, MFR 10-35 / PA6, RV 3.2 - 3.4 |

| Titre range | 165 - 4,400 dtex |

| Output capacity | 160 kg/h, 3.84 t/d |

Key features:

- Wide titre range

- High tenacity through unique heat treatmentsystem

- Fast and easy product changeovers

High output at low titres

Austrofil VERTEX spinning line

SML’s Austrofil VERTEX continuous filament line is specially designed to produce partially oriented (POY) or fully drawn (FDY) yarns. Optimised for PET processing, the VERTEX concept ensures high output in the titre range of 50–1,200 den.

This new demonstration line enables versatile possibilities on

- ultimate performance tests

- testing different polymers

- production of samples

| Austrofil VERTEX 2 x 8 | |

|---|---|

| Polymer | PET, PP, PA6 |

| Titre range | 50 - 1,200 den |

| Output | max. 270 kg/h |

Key features:

- Maximum flexibility in the use of different polymers

- Wide variety of different yarn types and product qualities

- Easy start up process with ramp-up function

- High-performance winding technology