Breadcrumb

SML DoubleCoat - exciting enhancements for breathable products

From breathable protective clothing to roofing membranes, from tents to surgical coverings, the number of potential applications has grown significantly since the successful market launch of SML’s patented DoubleCoat process. The key advantages of the technology include extremely thin functional materials with extraordinary properties in terms of breathability and adhesion – all of which comes with production costs kept to a minimum.

With its patented DoubleCoat process, SML has revolutionised the way that ultra-thin functional clothing and membranes can be produced with outstanding mechanical properties . Before the DoubleCoat process was invented, the thinner the functional layer or membrane to be applied onto a substrate like spunbonds or textile fabrics, the greater the probability that a so-called double-stage process would be necessary to build up the complete product structure.

“Thanks to SML’s DoubleCoat process, extremely thin composite structures can now be realised quite easily. This involves the extruded membrane joining the substrate in a single production step by adding an extra hotmelt layer,” says Johannes Danter, product manager for coating and laminating at SML. In the new process, the desired functional properties – such as increased adhesion, water vapour permeability or virus and bacteria barriers – can be easily adjusted by the coating weight of either the applied membrane or the hotmelt layer.

Once a good balance is found between the substrate, adhesive and extruded membrane, the DoubleCoat process is ready for a wide range of applications with unparalleled product features:

- Washable functional clothing such as breathable sportswear or protective clothing

- Outdoor applications such as tents, rucksacks or light tarpaulins

- Interior linings for automotive applications

- Roofing membranes for the construction industry

- Hygiene applications such as breathable layers in napkins/diapers

- Medical applications such as protective clothing and surgical coverings

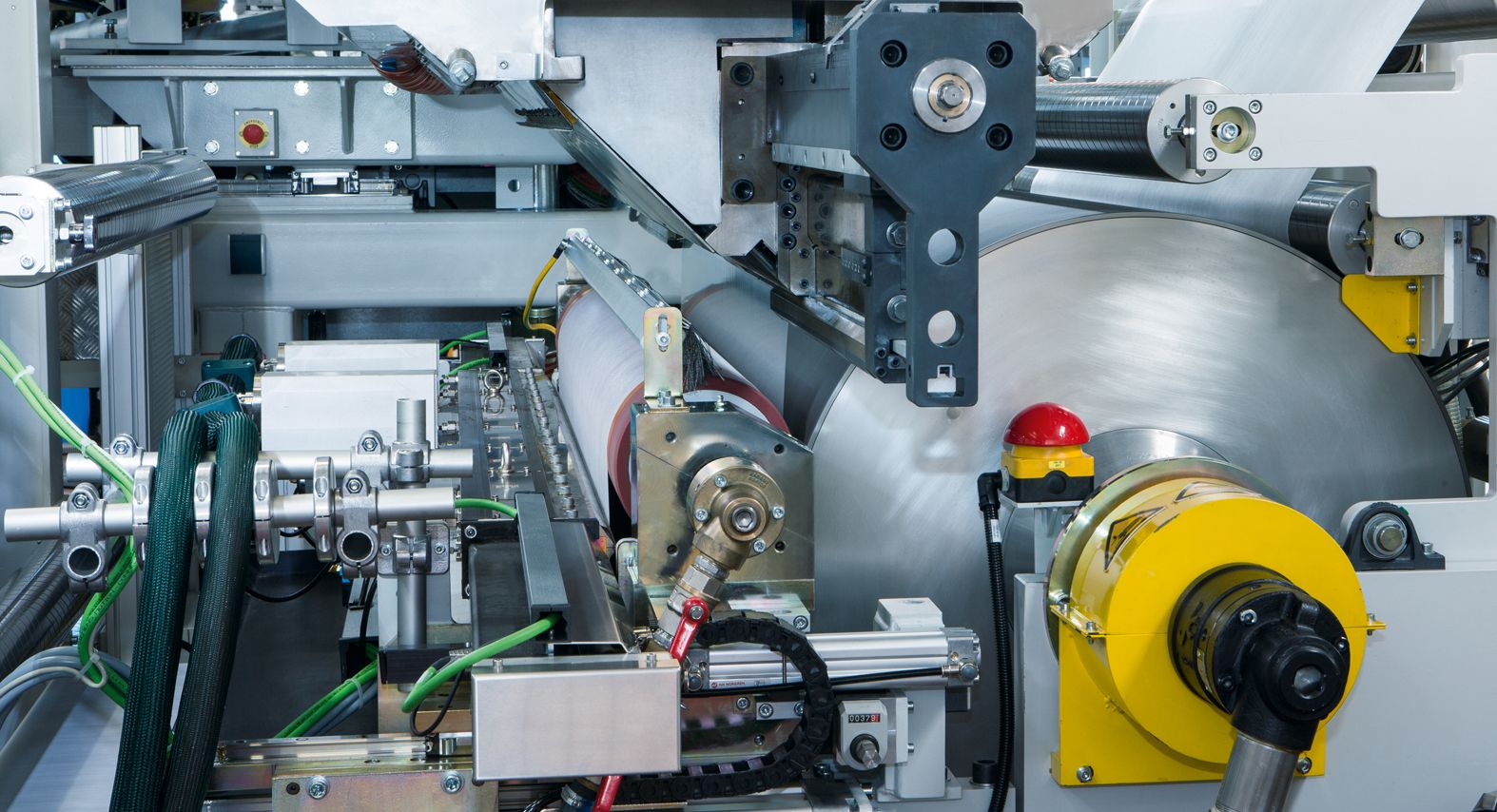

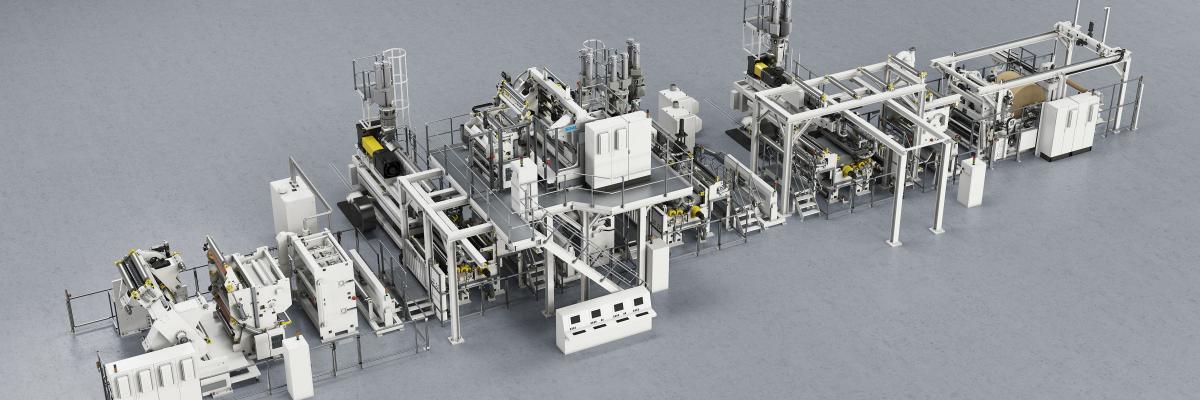

DoubleCoat technology can be easily integrated into SML’s FlexPack extrusion coating lines, combining extrusion coating with hotmelt lamination. The huge cost advantage of the DoubleCoat process comes courtesy of a massive reduction in raw material use and the consolidation of typically multi-stage processes into a single step.

Redlham, 14.05.2019