Breadcrumb

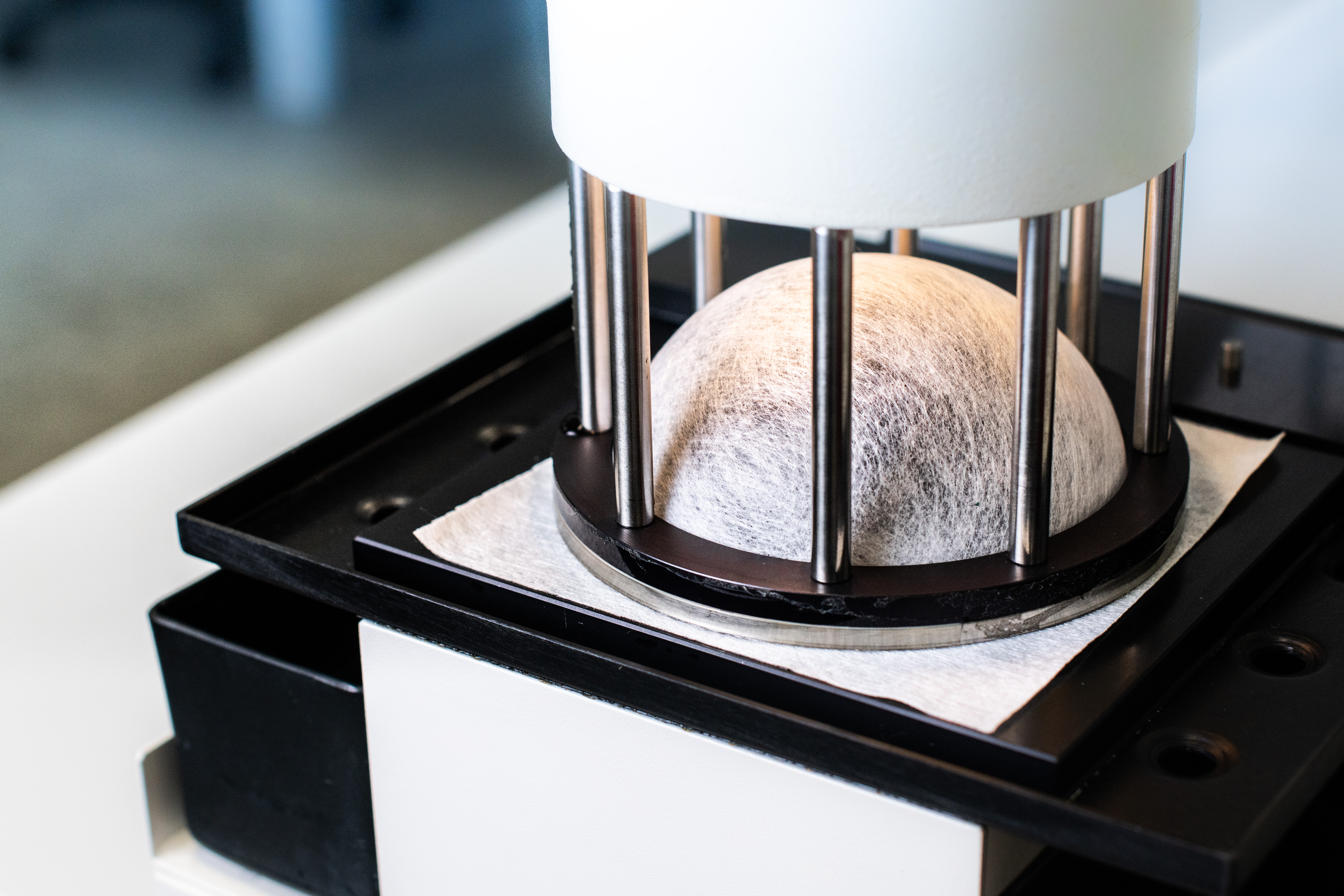

DoubleCoat technology avoids pinholes at ultra-thin coatings

The patented DoubleCoat process allows the manufacturing of ultra-thin, breathable functional film with exceptional properties at SML’s FlexPack lines. With this process, that is preventing pinholes, the way is open for new products with significantly optimised features – especially for the construction industry.

“Pinholes occasionally occur in the coating process, when fibre ends from the cloth are causing microholes in the coating-layer,” says Mario Höllnsteiner, Product Manager for coating and lamination at SML. In the course of trials to further optimise the adhesion between the layers in the DoubleCoat process, SML also found a way to effectively prevent the emergence of pinholes.

Lightweight structures with extraordinary water column

Coating-layers without pinholes are giving lightweight composite structures extraordinary properties. This allows, for example, the production of 40 gms TPU coating layers with an unreached high water column of more than 8 meters. Typically, coating-layers with such a water column have twice the thickness.

“The thinner the coating-layer, the better is the water vapour transmission rate of the product. Also for that reason, ultra-thin coating layers offer significant benefits,” explains Mario Höllnsteiner.

Minimising raw material, minimising costs

A central economical advantage of lightweight composite structures is the reduced raw material consumption at the manufacturing process, which typically results in lower production costs. The benefits of ultra-thin layers are highly required in the construction industry, i.e. for advanced types of roofing membranes. Beside that, the further developed DoubleCoat process is perfectly applicable for the production of single-use protective clothing, where both water vapour permeability and the lightness of the materials are a key issue.

Fully-developed DoubleCoat technology

At the end, the solving of the “Pinhole-Challenge” opens the door for a further range of improved products and new applications. With three lines in operation at customer sites, another one immediately before construction and one pilot line in SML’s Technology Center, SML’s FlexPack lines fitted with the patented DoubleCoat process are already established in the market.

Redlham, 11.11.2020