Breadcrumb

High-end vacuum system for demanding applications

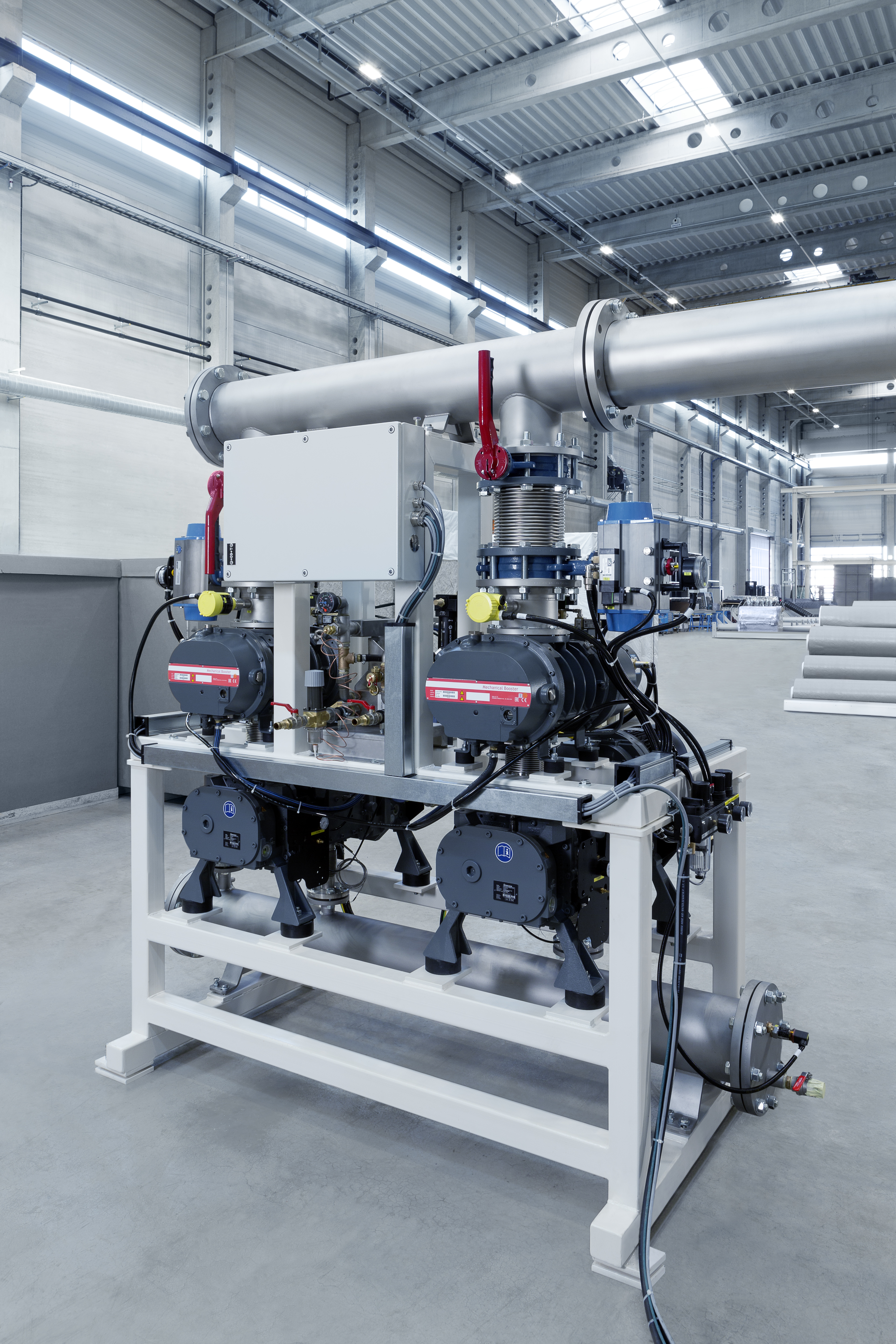

SML has developed a new series of vacuum systems for processing hygroscopic polymers which are sensitive to hydrolysis. The new systems are especially suitable for the extrusion of PET, PA or PLA and help to abandon time and energy consuming pre-drying processes, while keeping the final products at the highest quality levels.

The heart of the new series consists of dry-running, high-performance vacuum pumps with an efficient filtration system positioned upstream. Compared with conventional water ring vacuum pumps, the main advantages of SML’s new systems are the elimination of fresh water consumption, the high energy efficiency and the achievable vacuum levels.

While water ring vacuum pumps may provide absolute pressures down to 30 hPa, SML’s new solution is also capable of achieving absolute pressures below 1 hPa. Due to the modular design, suction capacities from 1,000 to 5,000 m³/h or more can be provided.

Like all machinery from SML, the new vacuum systems are characterised by the precise interaction of high-end components. The hardware is made entirely from stainless steel and the intuitive machine control integrates perfectly into the HMI of the respective extrusion unit.

SML’s new series of high-end vacuum systems were designed both for new extrusion units and for retrofitting of existing systems.

Highlights at a glance:

- Vacuum systems for the extrusion of hygroscopic plastics without predrying

- Absolute vacuum pressures from 1 to 10 hPa, suction capacity up to 5,000 m³/h

- Designed for the use in single screw and twin screw extruders

- Applicable to new extrusion systems and retrofits

- Modular design for either discontinuous or continuous operation

- Highend components and materials

- Energyefficient and eco-friendly due to dry-running vacuum pumps

- Perfect integration of the systems’ control units with SML’s SMILE control system

- Developed by SML – first hand service by SML technicians

Redlham, 28.04.2020